Information.

Article Date :

12 January 2013

Title :

Nando's Packaging

Cocoon Division :

Love Trees Project

Tags :

Nando's, Packaging, Love Trees Project

.................................................................

|

|

|

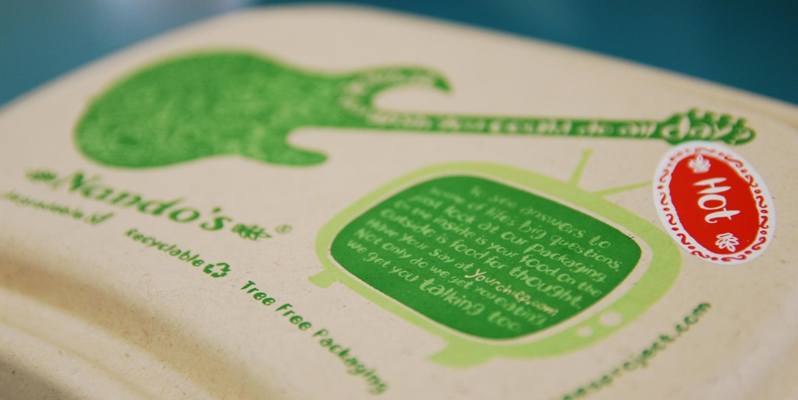

Cocoon and Love Trees developed a cohesive range of environmentally sound, disposable food takeaway packaging for Nando’s Australia, as an alternative to their existing paperboard cartons. Made from bio-pulp (annually renewable tree free, compostable clams, cartons and pales that utilizes existing waste fibre sources) and launched in 2009 this is, to the best of our knowledge, a world first for large scale franchise, brandable, moulded bagasse packaging that is entirely tree and petrochemical free.

Without doubt our largest undertaking to date, the project involved an extensive development process including comprehensive research into:

• The environmental credentials / bonafides of bagasse materials

• Sourcing

• Suitability for end use

• Post consumer phase issues such as recycling approval in the co-mingled recycling stream

• Product performance testing in commercial food franchise contexts.

The whole process from initial conception to live rollout spanned more than 18 months, including concurrent contract negotiations with the national franchise management and a variety of factories and material suppliers in China, credit sourcing, applications and ultimately funding to achieve start up, numerous design sampling and production refinements, presentations to an internationally attended conference on sustainability (‘Making a start’) in 2008 to pitch the concept and thereafter another major follow up presentation on areas identified for further investigation to the Nando’s Australia board and various major franchisees.

It was a significant shift away from the standard paperboard cartons and material that makes up the bulk of the disposable food packaging market, but one that long term emphasizes the importance of using annually renewable resources, and materials that require no petrochemical coatings or polymers to perform as food safe containers in a wide range of temperatures and operating conditions.

In addition we were the first company worldwide to be able to effectively brand this material, in a commercial / large scale context, using eco-friendly, non-toxic, food safe dyes, helping make the transition from an existing, but limited technology, to one that has far wider applications in respect of branding, marketing and promotion.

The shift to a tree free philosophy is one that we firmly believe in, as the use of forest + plantation timber for disposable consumables is both unsustainable and ecologically damaging. Moreover the requirement of most paper products to be coated to avoid toxic or non-food safe particle and chemical transfer means that tree based pulp products are limited in their true compostability and bio-degradability. Essentially if you have to use bleaching, chemicals and petroleum based coatings to operate safely as a food carton container, then where and how the cartons are disposed of can become problematic.

Petrochemical, bleach + BPA free, our products do not leach harmful substances back into the soil during and after decomposition and as such can be truly considered as compostable and fully bio-degradable. Where local waste stream management may not yet have the infrastructure to deal with collection, sorting and processing of high volumes of compostable materials (barriers to market are varied but localized councils around Australia are beginning to offer this service) we felt it was important the product be approved for use in the co-mingled recycling stream in the medium term, to at least minimize the impact they have on the environment and begin the push away from harmful + unsustainable landfill practices that still dominate our waste streams.

Since rollout nearly 3.5 years ago the products themselves have gone through a number of refinements and improvements based on feedback from store level employees and customers as well as product performance reviews and redesign of both the items and a number of elements of the production process itself.

|

|